The Definitive Guide to Digital Printing

Some Known Details About Digital Printing

Table of ContentsThe Best Guide To Digital PrintingSome Of Digital PrintingHow Digital Printing can Save You Time, Stress, and Money.

Digital printing also calls for marginal configuration. Here are the vital methods in which digital printing sustains greener methods: One of the significant ecological benefits of electronic printing is minimizing waste (Digital Printing). Conventional printing methods, like lithographic printing, frequently waste substantial quantities of paper and ink during the configuration stage.

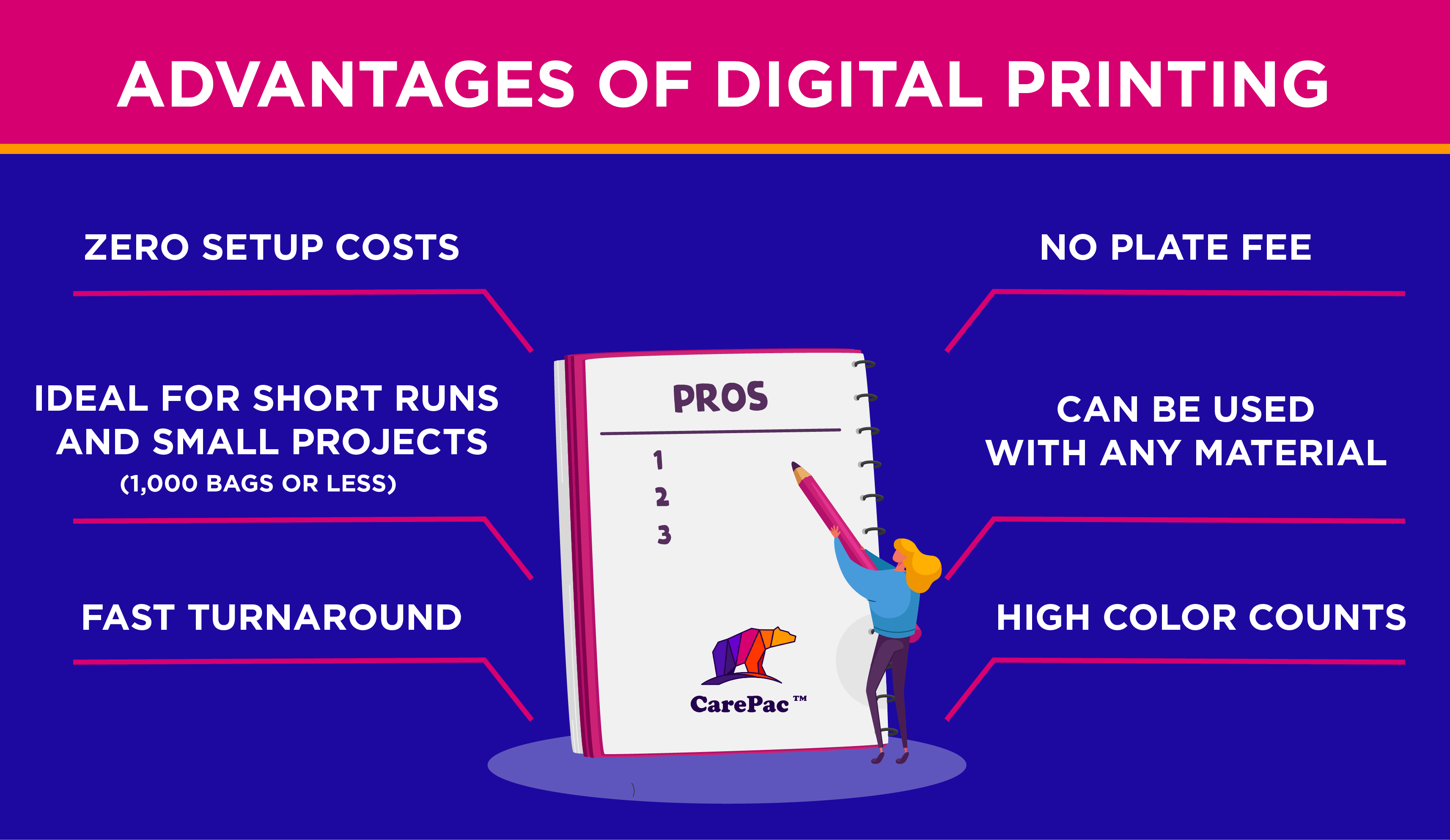

Digital printing machine eliminate the need for these plates, significantly reducing arrangement prices. Digital printing machine can include variable data right into your prints, which permits for extremely customized advertising and marketing products (Digital Printing). By customizing your advertising and marketing products, you can boost involvement with prospective clients and boost the chances of converting them right into actual consumers

Digital printing machine supply exceptional shade consistency and precision, leading to higher high quality prints. With electronic printing, you can be sure that the color of your prints will correspond from one print work to the following. A number of years earlier, several consumers did not approve direct-injection digital printing since the high expense. The acquisition expense of an established electronic printing equipment goes to least 150%of the conventional printing and coloring tools, which boosts the.

Rumored Buzz on Digital Printing

In order to stop rust of the nozzle, the ink for electronic printing is extra costly than the ink for conventional printing, and additional ink filtration is necessary throughout the printing process. In digital inkjet printing, the pattern is straight printed on the fabric, eliminating the plate making in rotating screen printing. Yes, are more expensive than conventional printing inks, but the digital printing process can save ink intake.

Today, the electronic direct-injection printing press has actually gone from proofing to the stage of medium-sized and large-sized production. The electronic direct-injection maker has actually experienced the promo period and got in the development and maturation period. Both printing residences and brand name proprietors understand the advancement potential of electronic printing, and want to boost investment in digital printing. The print top quality can often even rival that of countered printing. Digital printing is a lot more economical Go Here for short print runs since it requires much less pre-press activities and much less configuration than offset printing. If a mistake in offset printing is not captured before the plates are made, it will certainly be very pricey to make new ones. While every read what he said person best regards really hopes that mistakes will be stayed clear of, it is reasonable to prepare for their possible adjustment. In addition, its precision is really high. This makes sure uniformity in appearance throughout the board, decreasing the chance that any piece will require to be tossed out due to flaws. Guaranteeing home plates are in location, the ink secret is adjusted, and all the required changes have been made is a lengthy process when countered printing. Minimized pre-press actions imply less time is needed to establish up the press. This leads to a significant velocity of turnaround time. When you need published products rapidly, this is a fantastic choice. Digital printing can be a lifesaver when you obtain an order in the nick of time.

Variable data printing, such as direct mail with customized codes and addresses, is preferably matched for electronic printing. Digital quick printing only needs four steps of layout, review, printing and binding to obtain everything done. Digital quick printing has an unequaled benefit: print on demand.